Rodd

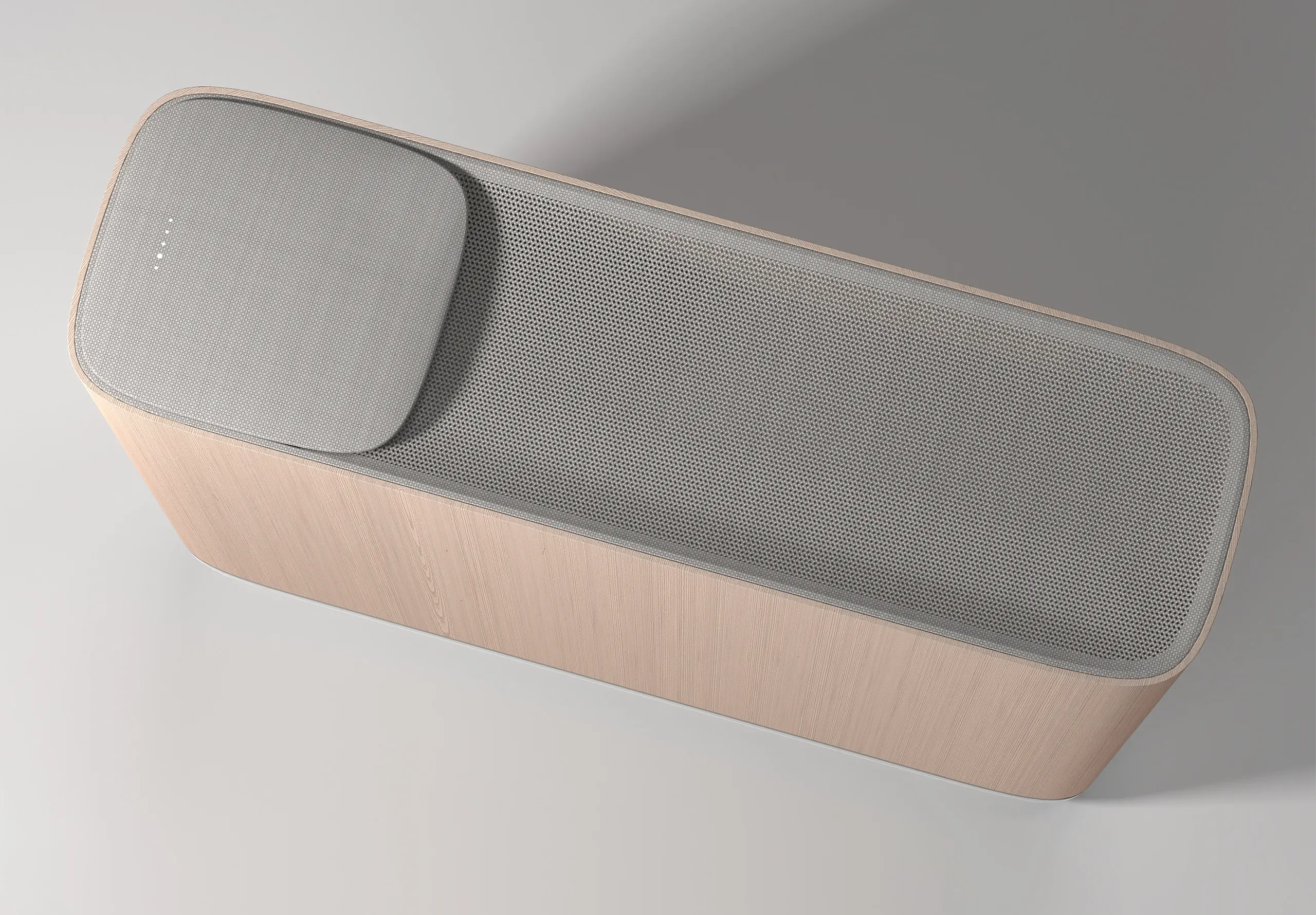

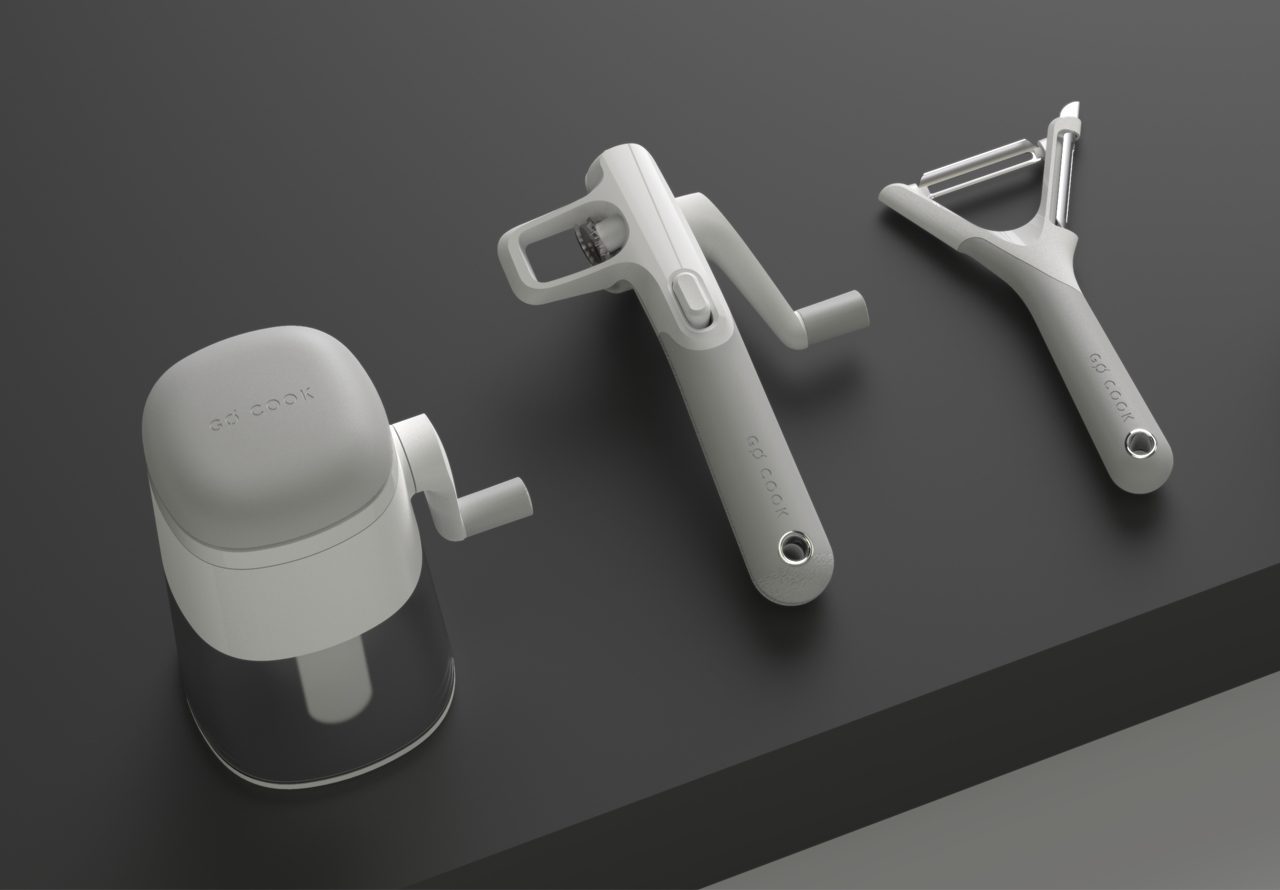

Rodd is a design and innovation studio recognised for consumer innovation and the highest level of design execution across product, brand and digital.

Together, we’ll design your next chapter.

We work within the inner circle of some of the world’s leading consumer brands and sustainable innovators.

For two decades, we have been at the forefront of brand innovation, helping our partners navigate strategic challenges and tell their story through beautifully executed design.

Together, we will help your brand decipher what’s right for your progress, for people and the planet.